After the technical demonstration and experimental demonstration of our r&d team, we have also started to promote our energy-saving and efficiency improvement plan for CFB to customers.

Based on the excellent anti-wear effect of the grille anti-wear technology developed by our company, we further tested the pouring material in the high-wear area of the heating surface of the released boiler, and the grille anti-wear plate of our company was used to resist the occurrence of high wear. Thus, on the basis of realizing the stable operation of the boiler, the heated area is released, so as to directly increase the thermal output of the boiler and realize the energy saving and efficiency increase of CFB boiler.

Our energy-saving and efficiency enhancing technology has been applied to four CFB boilers from three manufacturers since it was promoted last year. From the current use, the effect is very good. The longest period of the project of replacing the grille with castable has been more than 14 months up to now. There is no obvious wear and thinness in the transformation area. The boiler runs stably and the thermal output increases obviously. In addition, this technology can realize the change of heating area in the boiler without changing the boiler design, so as to realize the effect of adjusting the boiler temperature. Its extended application and utility, we are also actively collecting data, and rigorous demonstration.

We hope that the grille anti-wear technology developed by our company can lead a small trend in the industry and liberate greater productivity of our customers on the original basis.

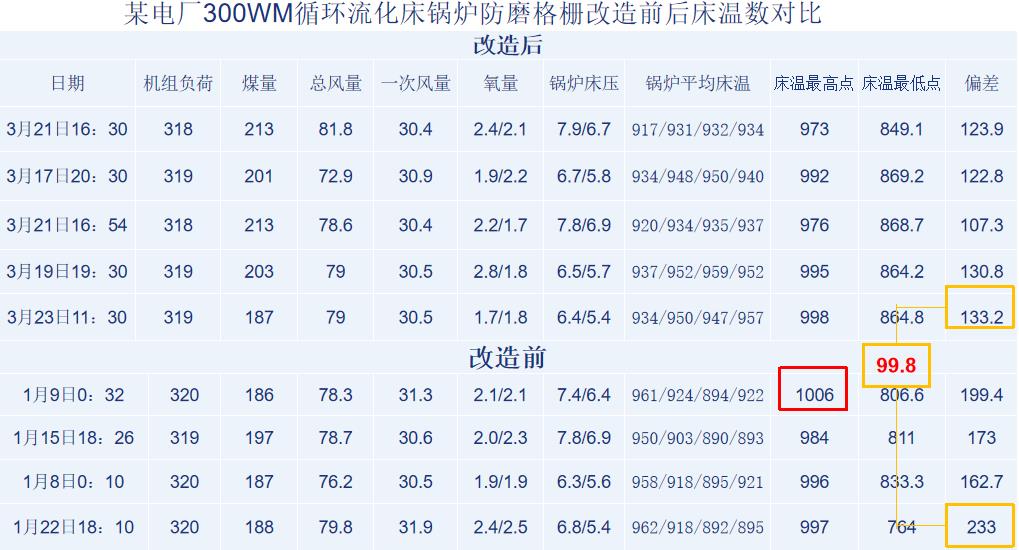

The following is part of the data and information collected by the energy saving and efficiency increasing project of our company:

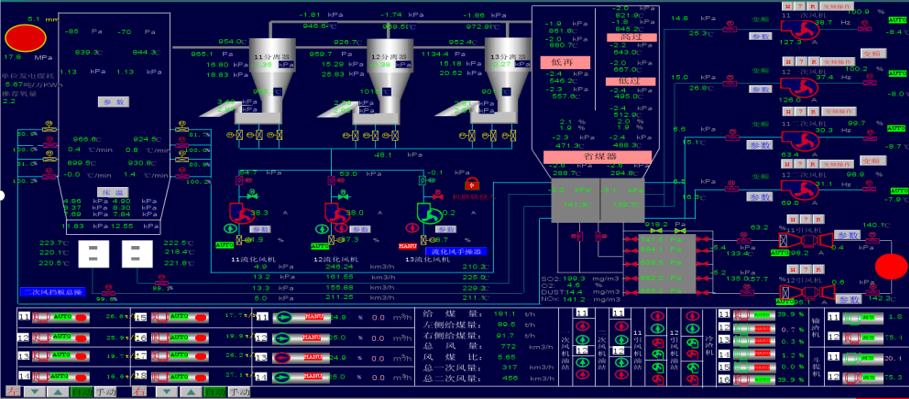

DCS diagram before grille modification:

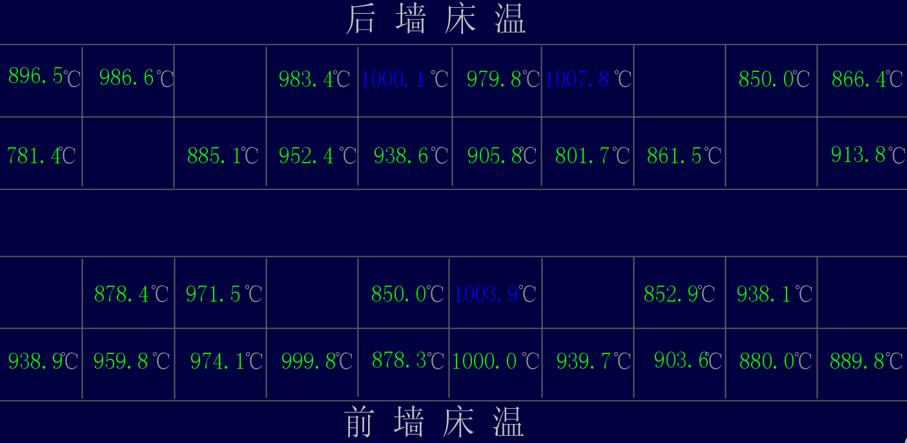

DCS diagram after grille modification:

It can be seen from the comparison of the above grilles before and after the transformation that the grilles anti-friction technology has obviously helped the power plant to realize the boiler lowering bed temperature requirements.

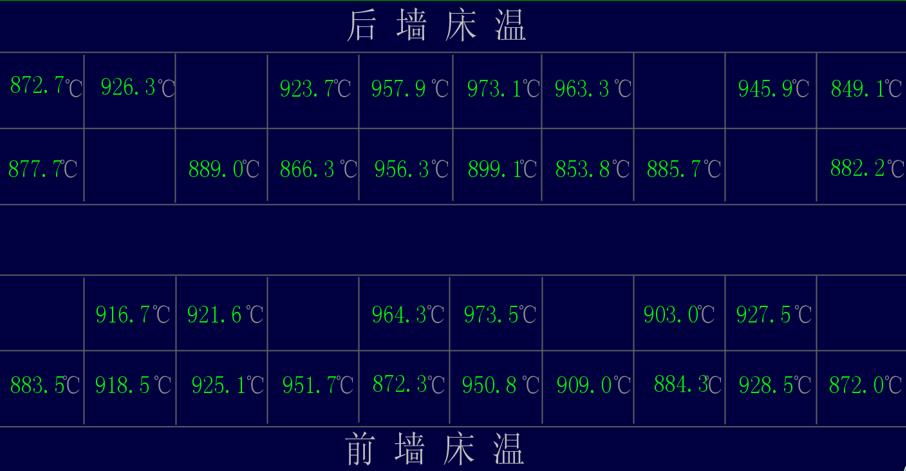

The following is the bed temperature comparison of a power plant 30WM CFB boiler before and after the transformation:

Please feel free to contact me!

Please contact us for more information+86-18062456085