Circulating fluidized bed(CFB) boiler is the clean coal combustion technology with highest industrialization degree at present. Its fluidized combustion design and circulating furnace characteristics enable it to complete the full combustion of refractory solid fuels (such as coal gangue, oil shale, urban garbage, silt and other wastes, etc.), so as to realize energy saving and environmental protection utilization and be widely used.

CFB boiler in practical application, however, due to the reason, the characteristic of combustion in furnace wear problem is very prominent, especially the boiler burning inferior fuel (such as coal gangue, waste of blending ratio and high ash content) when the wear problem is more serious (as shown in the figure below), the boiler caused by frequent non stop, short operation cycle, greatly affect the security and economy.

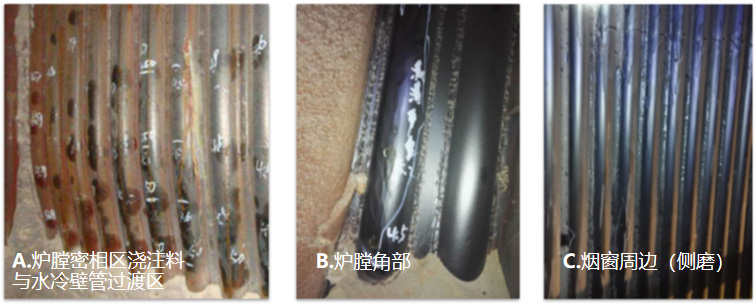

We summarized the wear characteristics and rules of CFB boilers, and the wear mainly occurred in the following areas (as shown in the figure below) :

1. Transition area between castable and water-wall tube in dense phase area of furnace;

2. Four corners of furnace;

3. Periphery of smoke window (side grinding);

4. Local convex part of heating surface;

5. Anti-wear coating interface area;

To solve the wear, first we need to objectively understand the circulating fluidized bed wear:

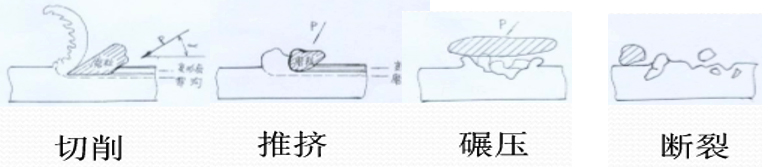

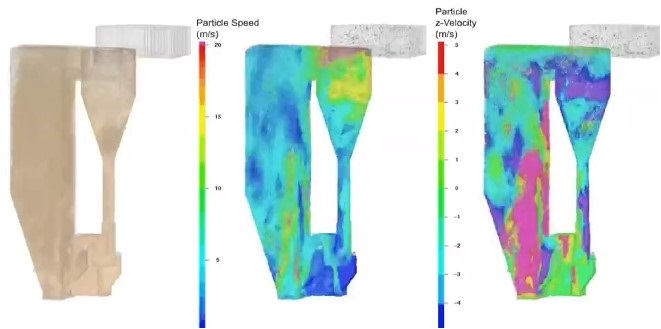

For circulating fluidized bed boiler, its wear is mainly manifested as abrasive wear, abrasive wear refers to the particles of various materials or protruding objects in contact with the surface of the parts, so that the loss of surface material phenomenon, is the role of hard particles or prominent points caused by material transfer.

Its manifestation is shown in the following figure:

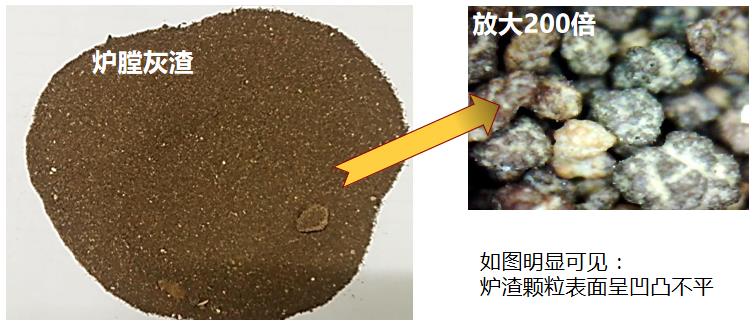

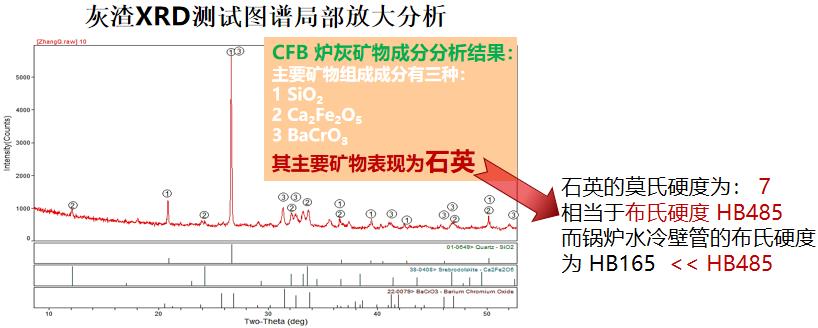

Study on the ash burden of circulating fluidized bed boiler:

In this paper, the samples of circulating fluidized bed boiler ash from different factories, regions and types of coal are studied and tested. See as below pic shows , the surface of ash slag is obviously uneven after amplification, and the hardness of ash slag is also as high as HB485, much higher than the hardness of water wall tube HB165 .

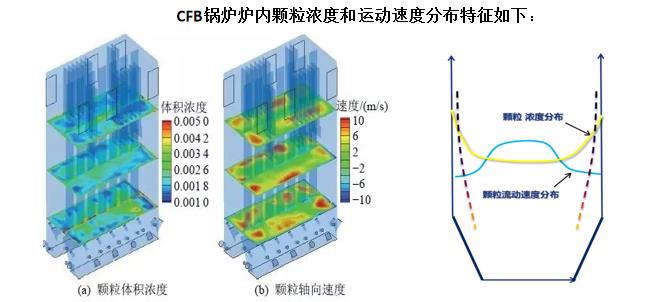

According to the operation principle of circulating fluidized bed boiler and combined with the main wear area in the furnace, we also made a detailed study, and the rule is as follows:

1. At the same level:

The center concentration is small, moving upward;

The concentration is high near the boundary wall and usually flows downward.

2. Axial direction of furnace:

The particle concentration near the side wall is smaller on the top and larger on the bottom. Particle velocity near the sidewall: low on high.

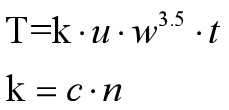

According to the operation rules and data obtained from the study, the wear analysis of water-wall tube wear formula is as follows:

Among them, the

T --wear, g / ㎡; μ -- material concentration,g/m3;

W -- material flow rate,m/s; T -- time,h;

K -- wear coefficient; N -- material impact rate;

C--material wear coefficient (closely related to material composition);

Conclusion:

the velocity of material is the main factor affecting wear, followed by the material concentration.Based on the above research results, we conclude:

The water wall wear of CFB boiler is mainly caused by the high velocity and high concentration of the materials on the surface of the water wall. Therefore, as long as the high velocity of the materials on the surface of the water wall can be effectively controlled and the distribution concentration of the materials on the surface of the water wall can be improved, the problem of wear on the surface of the water wall can be effectively contained.

According to this theory, we developed the grille anti-wear technology, and after years of experimental practice and improve the grille anti-wear technical details, finally has now been able to fully commercial application and widely acclaimed solution - thermal conductivity grille anti-wear technology.

C--material wear coefficient (closely related to material composition);

Conclusion:

the velocity of material is the main factor affecting wear, followed by the material concentration.Based on the above research results, we conclude:

The water wall wear of CFB boiler is mainly caused by the high velocity and high concentration of the materials on the surface of the water wall. Therefore, as long as the high velocity of the materials on the surface of the water wall can be effectively controlled and the distribution concentration of the materials on the surface of the water wall can be improved, the problem of wear on the surface of the water wall can be effectively contained.

According to this theory, we developed the grille anti-wear technology, and after years of experimental practice and improve the grille anti-wear technical details, finally has now been able to fully commercial application and widely acclaimed solution - thermal conductivity grille anti-wear technology.

Please feel free to contact me!

Please contact us for more information+86-18062456085